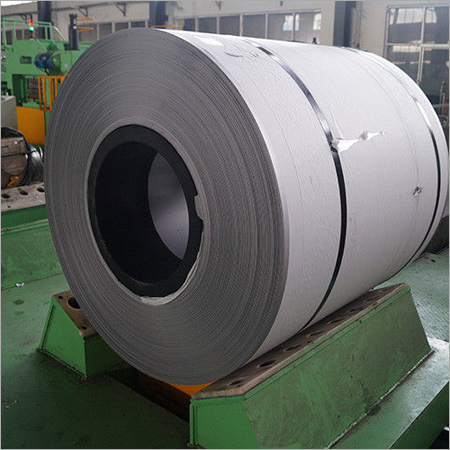

Hot Rolled Plain Coil

Product Details:

- Surface Treatment Hot Rolled

- Material Mild Steel

- Technique Hot Rolled

- Grade IS 2062/ ASTM A36/ EN10025

- Coil Thickness 1.50 mm to 20.00 mm

- Coil Weight Variable as per customer requirement

- Coil Length Customizable as per requirement

- Click to View more

X

Hot Rolled Plain Coil Product Specifications

- IS 2062/ ASTM A36/ EN10025

- 1.50 mm to 20.00 mm

- Soft to Medium

- Variable as per customer requirement

- Hot Rolled

- Hot Rolled

- Mild Steel

- Automobile, Engineering, Construction, Structural Fabrication, Pipes & Tubes

- Customizable as per requirement

- Metallic Grey

- 1000 mm to 2000 mm

- 250-350 MPa

- As per relevant standards

- IS, ASTM, JIS, DIN

- Standard export packaging in coils

- In Stock

- Mill Edge/Trimmed Edge

Product Description

A steel coil that has been rolled at a high temperature to get a flatness and smooth surface is called a hot rolled plain coil. The heated steel is passed through a number of rollers to get a thin sheet of steel. The coil finds use in a number of industries for making consumer goods, structural components, and automotive components because of its exceptional properties. Customers can place orders for the hot rolled plain coil in desired size and thickness. They can form and shape the coil easily into desired products.

Versatile Material for Diverse Applications

Hot Rolled Plain Coils are favored for their adaptability and reliability in various sectors such as construction, automobile manufacturing, engineering projects, and structural fabrication. The products customizable width, thickness, and coil length ensure it can be tailored to specific project requirements, making it an excellent choice for both large-scale and bespoke applications.

Manufactured to International Standards

Each coil adheres to leading standards like IS, ASTM, JIS, and DIN, ensuring dependable mechanical properties and consistent quality. The products yield strength ranges from 250 to 350 MPa, while the hardness remains between soft to medium, making it suitable for fabrication, welding, and forming processes. Users can trust in its durability and performance under various operating conditions.

FAQs of Hot Rolled Plain Coil:

Q: How are Hot Rolled Plain Coils produced?

A: Hot Rolled Plain Coils are produced using the hot rolling technique, where mild steel billets are heated above their recrystallization temperature and then rolled into coils of specified width, thickness, and edge type. This process results in a smooth, metallic grey surface and structural integrity suitable for numerous applications.Q: What applications can benefit from these hot rolled coils?

A: These coils are ideal for use in the automobile, engineering, construction, structural fabrication, as well as the manufacturing of pipes and tubes. Their customizable dimensions and mechanical properties make them a versatile material for both heavy industry and precision engineering.Q: When should I choose mill edge or trimmed edge coils?

A: A mill edge coil is supplied as rolled without additional finishing on the edges, suitable for general applications where precise edge finish isnt critical. Trimmed edge coils are processed to remove irregularities, providing a cleaned and uniform edge for projects demanding higher aesthetic or fitting requirements.Q: Where are these coils commonly utilized within India?

A: Hot Rolled Plain Coils are widely used across India in industries ranging from automotive production hubs to construction sites, engineering workshops, and pipe manufacturing units. They are favored by exporters, manufacturers, suppliers, and traders due to their wide availability and adherence to quality standards.Q: What is the process for customizing coil weight and length?

A: Coil weight and length can be tailored based on the clients specifications during the manufacturing phase. Customers simply need to specify their project requirements, and the coils are then produced and cut accordingly, ensuring optimal utility and minimizing material wastage.Q: How does the surface treatment benefit the end user?

A: The hot rolled surface treatment imparts a smooth and consistent finish, enhancing the materials weldability and formability. This results in easier downstream processing, whether the coil is being fabricated, cut, or shaped for specific end uses.Q: What are the advantages of choosing coils with yield strength of 250-350 MPa?

A: Coils within this yield strength range offer a good balance between ductility and strength, allowing for structural flexibility while maintaining durability. This makes them suitable for load-bearing structures, frames, and safety-critical components in construction and engineering applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Galvanized Metal Coils' category

|

ASIAN STEEL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |